Yesterday we attached the webcam to our box. Afterwards we fine tuned the angle of the beamer and the mirror. We did a couple of quick application tests (photo app & smoke). The dimensions of our screen are not optimal because the ratio is not 4:3, but we will adjust this with software.

11 May, Harry van der Veen

The silicone rubber sheets we prepared are made out of 2 fluids that you combine and then they cure over time. The fluids come from a company named Wacker Chemie AG. Their website is located here: http://www.wacker.com

10 May, Harry van der Veen

So this morning we pulled our screen from the oven ;), to further assemble it.

10 May, Harry van der Veen

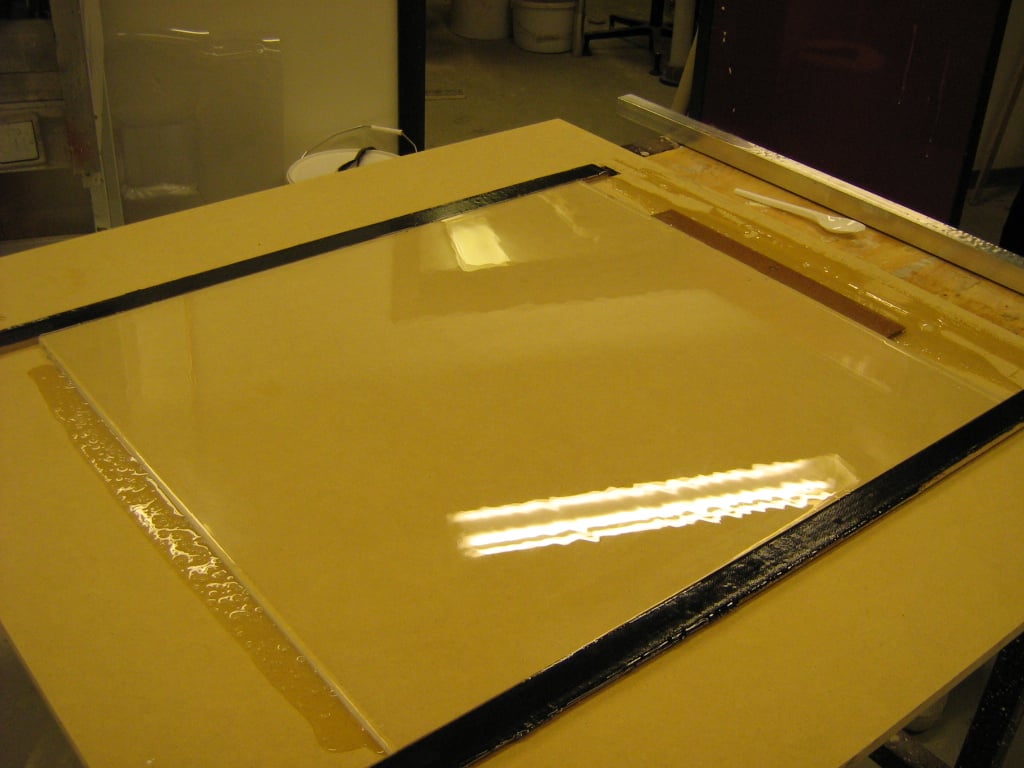

So Tuesday we made 2 test samples of silicone rubber sheets, that worked very well. Therefor we made another one for our 60*60 prototype.

10 May, Harry van der Veen

I'm releasing an alpha version of my multi-touch display how-to guide.

8 May, Harry van der Veen

Today Peter and I have been creating 2 silicone rubber test sheets. 1 sheet is 1 mm thick and the other one is 2 mm thick. So we can test which thickness is better. This sheet will be placed between a projection screen and the acrylic to improve the coupling between the two.

5 May, Harry van der Veen

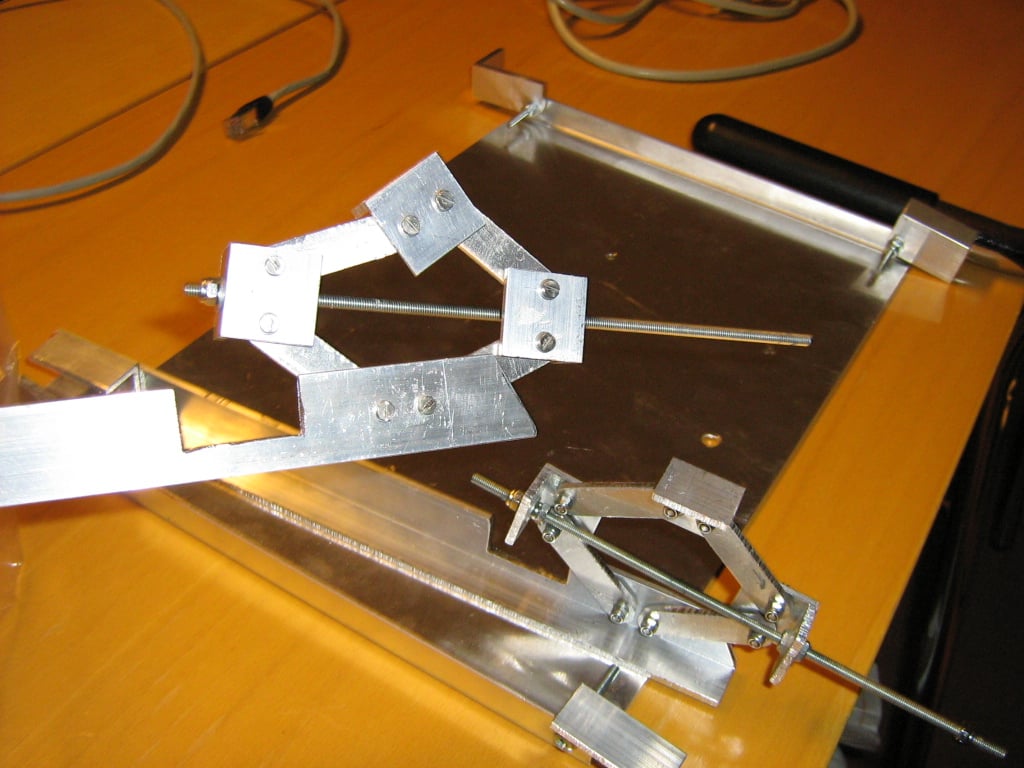

Yesterday Peter and I worked in the metal lab on finishing the mechanism that'll hold the beamer inside the box. It's finished now and should only be attached inside the box now.

3 May, Harry van der Veen

I ran into this video on youtube, from Falcon4ever , one of my Dutch homies from the NUIgroup community, check out his video below.

Sho stick

Sho stick